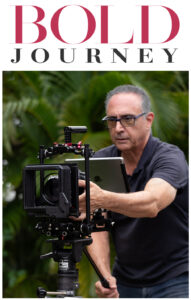

A CAMERA LOST, A PASSION FOUND

My affair with photography began in August 1964 at the world’s fair in flushing queens New York. I was 8 years old, my parents, siblings and I had just had lunch at what I remember to be a restaurant. My father realized he left his camera behind and we hurried back to get it…. my father asked our waitress if anyone turned in his camera that was left behind at the table we had just ate lunch. Hearing “no” was a disappointment to my father…. but seeing the camera at my eye level tucked behind the utensils at the waitress station I grabbed it and proudly announced that I had found it. My father said when I get older I could have that camera, a twin lens 35mm Bolsey with rangefinder range-finder focusing.

Fast forward a few years and countless requests to use the camera… I used allowance money to buy my first roll of film at the local pharmacy and returned it to the same pharmacy for processing…

FINDING MY PATH

I managed to convince my mother to buy a black plastic developing tank (Yankee) and a chemistry kit (Kodak) at Kingsbridge camera shop on Fordham road… and my first successful roll of film was mostly of my dog Paco. I stared at those reversed little B&W images for what seemed like an eternity.

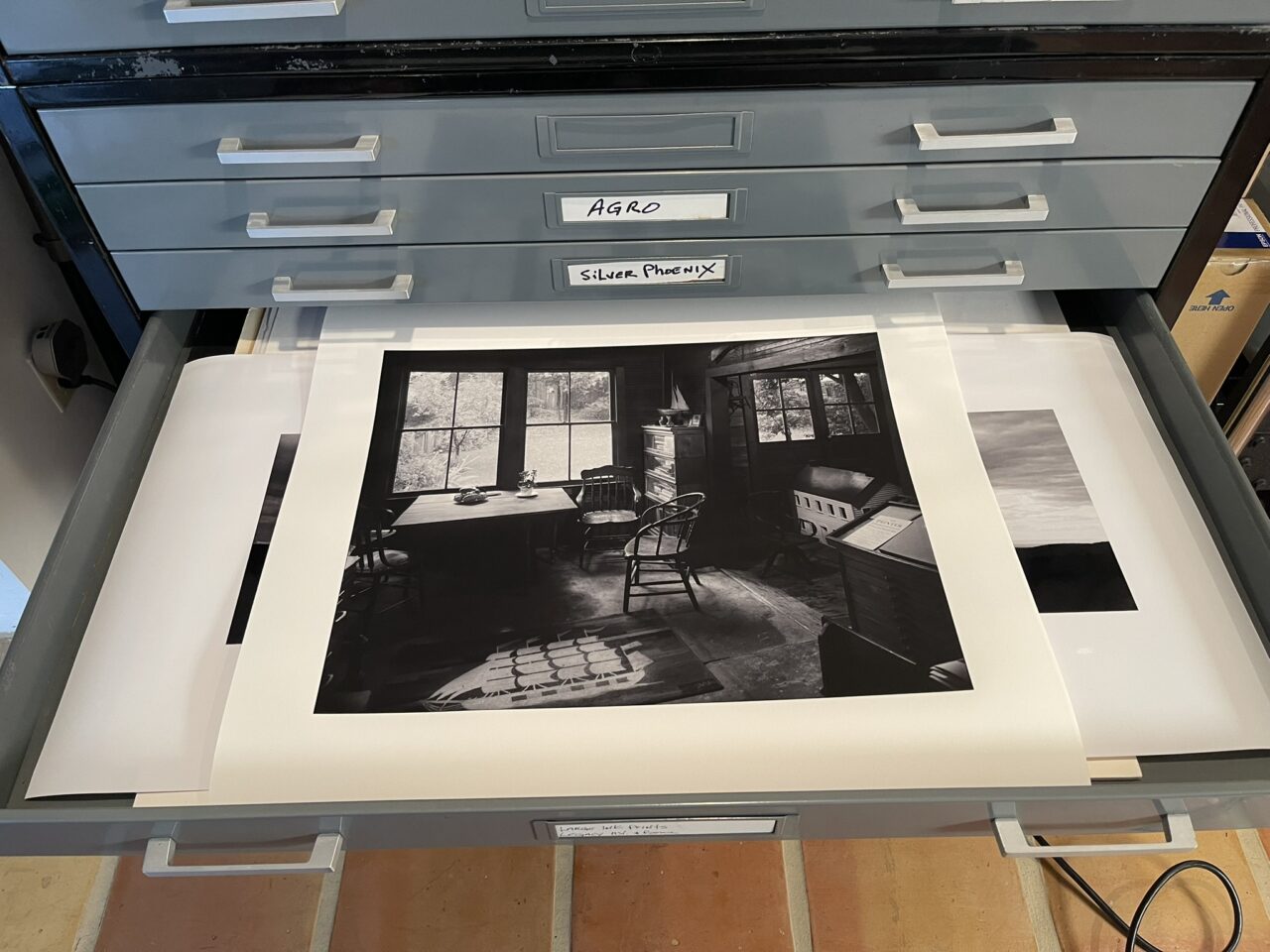

My fascination and determination was rewarded with a willingness by my mother to take me back to Kingsbridge camera to buy a Bogen enlarger, 3-4×5 trays and a box of 4×5 paper (DuPont Velour matte surface)… in a not so light tight closet and a 29.95 enlarger I made my first prints, I was 12 years old. Later that year I discovered books by Ansel Adams and his method of print visualization, meticulous control of processing that allowed complete control of tonal values to achieve the print he pre-visualized. Photography in this context of visualization and execution appealed to me as an artist, and unknowingly that experience altered the direction and purpose of my art.

H.S. ART & DESIGN, NYC

I had applied to Art & Design HS in NYC during 1970 and was starting what was intended to be a career in art & illustration. After the start of my junior year in October of 1972 I changed my major to Photography. By my senior year of HS I was shooting w/ a 35mm Minolta SRT101, 6x6cm Hasselblad 500C and a 4×5 Speed Graphic… I had a functional darkroom, aka a bigger walk-in closet and very understanding parents that allowed my domination of the kitchen sink when I was printing.

ENDLESS OPTIMISM & DISAPPOINTMENT

I applied to a few colleges and choose SUNY-FIT for its proximity, cost and brevity… Prior to graduation I was working as a freelance assistant in NYC, after graduation, I worked full time assisting many well-known commercial photographers, a learning experience beyond photography, filled with challenges of self-reliance.

A photographer I was working for (Fred – studio on 23rd St) had become ill and was not able to work, his agent asked me to do a sample shot (unofficially) of a new product line for Revlon cosmetics. My whimsy and confidence to play with the cosmetics and my prior history in painting compelled me to smudge and smear the cosmetics on the white Lucite background…. like a painter would mix colors on a palette… these test shots were delivered to the agency by the agent despite the lack of conventional “product beauty shot” … my creativity became Revlon’s “pallet of colors campaign” summer 1976. The photographer I worked for did not return to work and his agent delivered told me I would no longer be working for Fred…

REBOUND FULL COURT PRESS

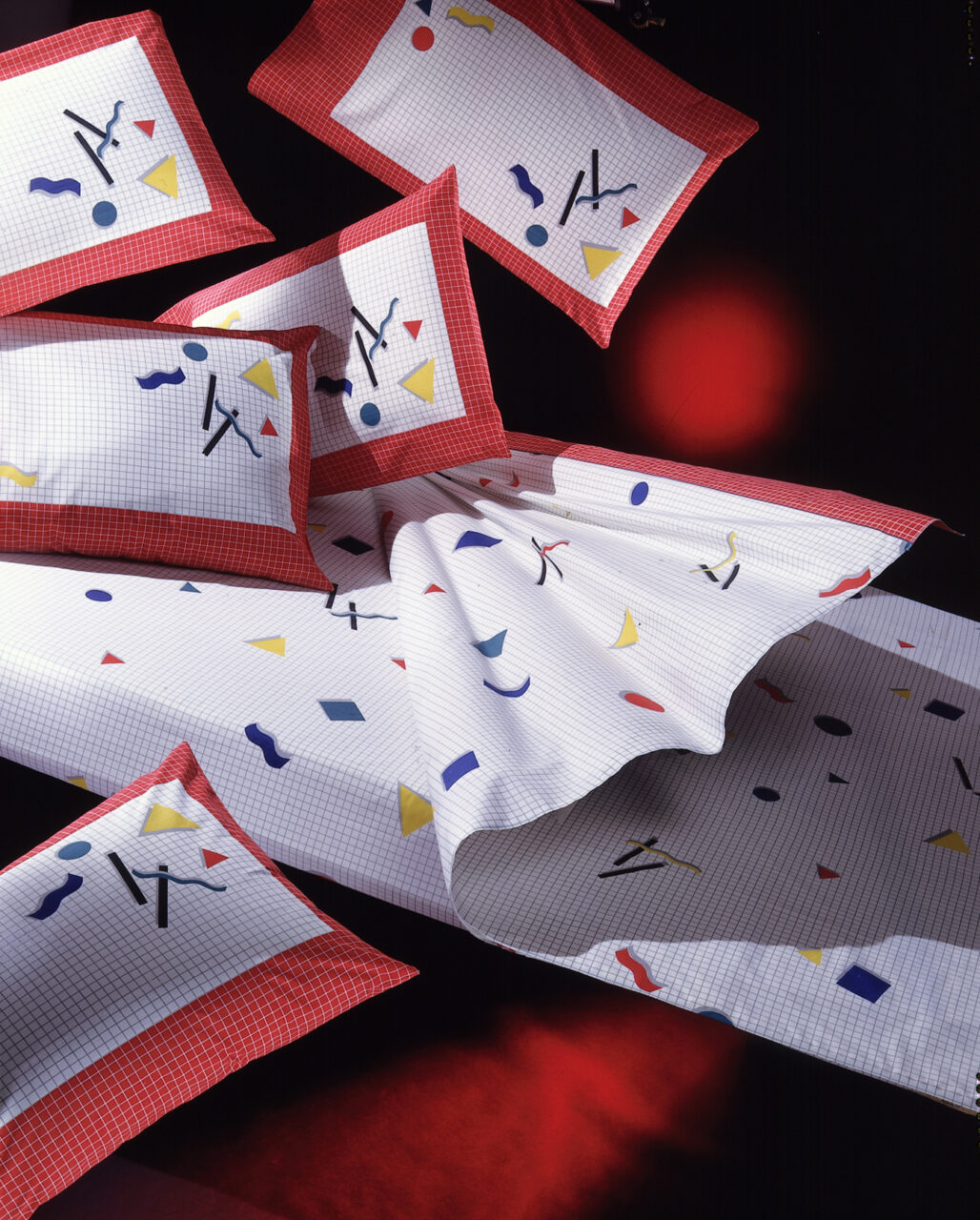

I responded to a job posting and promptly started another job at a large catalogue studio on Park Ave & 20th St. In my first year (age 19) I was asked to shoot 3 full page ads for K-Mart that appeared in parade magazine… again only by chance it was a rush assignment and I was willing to work late into the evening for the chance to do more than load film holders. I built a small set that looked like a beach location, I shot it with a bare bulb Ascor Sun-tube with 6 daisy chained powerpacks… 6 sheets of 11×14 Ektachrome transformed an unknown kid from not having a name to the talk of the studio.

My portfolio and experience opened doors to work for top photographers in NYC. I printed Arnold Newman’s 50 year retrospective for the Light Gallery in NYC and his Great British book and show sponsored by the London Times. I also worked freelance for Ray Kelman, Richard Avedon, Gary Bernstein, Al Franckevich, Bert Rockfield, Lowell McFarland, Irving Penn and then a full time position with Lionel Freedman (my most influential mentor).

SPRINT FINISH TO A MIRAGE

My years of assisting NY’s Greatest photographers opened the door to a staff position at a large production studio in NY and FL for six years, before establishing myself as an independent freelance photographer. In the past half century plus my clients and assignments have spanned multiple generations of change and trends beyond the changing cultural styles and technologies to the transition of print media to digital media to social media. My love affair with photography has remained unchanged through the challenges, disruptions, detours and transitions of life.

Most Recent Comments